Cutout fitting and accessory

Compare EC Insulators quality and technical expertise

Interchangeability:

EC INSULATORS design a cutout that could

interchange fuse-holders and mounting assemblies with those of another

manufacture. Standard Type C fuseholders and mounting assemblies are mutually

interchangeable with S&C Type XS and ABB Type ICX cutouts. (within the same

voltage class).

Application

The Type C-Polymer Loadbreak Cutout is

available for ap-plication on 15 and 27kV distribution systems. The addi-tion

of the arc chute expands the flexibility of the

protective devices family by providing loadbreak capability for cutouts

and disconnect solid blade units. The loadbreak cutout provides short circuit

protection to utility lines with the added feature of a loadbreaking function.

The loadbreak cutout is applicable for

transformer and capacitor bank switching or line sectionalizing. Loadbreak

cutouts provide protection from overloads that just melt the fuselink through

the maximum interrupt capacity of the fuseholder. They also provide loadbreak

capability through 300 amperes.

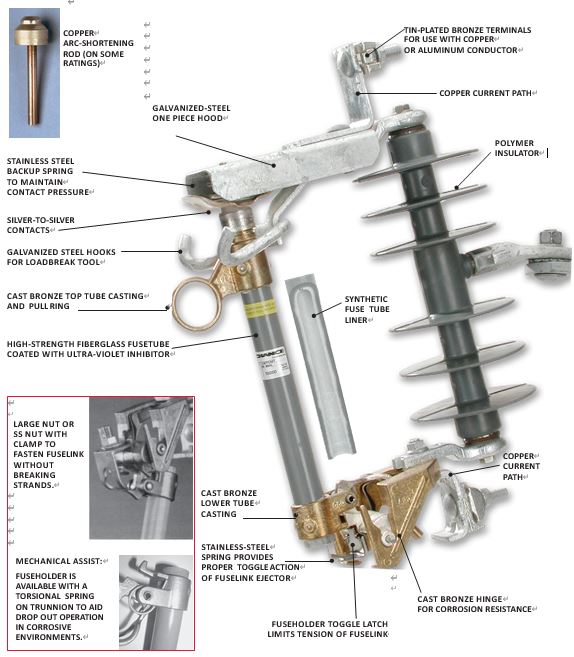

Design

All design features and most components of

the load-break unit are identical to those incorporated in the Type C-Polymer

standard cutout. The loadbreak portion of the Type C-Polymer Loadbreak cutout

is a heavy duty, reliable load interrupter that provides a positive visible

loadbreak. A common loadbreak mounting assembly will accept the Chance Type

C-Polymer 100 amp and 200 amp loadbreak fuseholders or a 300 amp loadbreak

disconnect blade. The Type C-Polymer LOADBREAK fuseholder is not designed to be

interchangeable with any other manufacturer’s cutout.

Ratings/Specifications

15kV Type C-Polymer loadbreak cutout has a

maximum design voltage rating of 15kV. There are no voltage restric-tions on

applicaton to grounded wye, ungrounded wye, or delta systems having maximum

operating voltages (line to line) equal to or less than the cutout maximum

design voltage rating.

Advantages & features ;

The total installed cost of a ECI

cutout-arrester com-bination is less than the total installed cost of

separately purchased components. The combination units install faster, more

economically and take up less space in storage, transit and service. Each

combined unit takes up a minimum of space on the crossarm and has a favorable

weight distri-bution for minimal off-center loading. The field-proven quality

of both cutout and arrester assure consistent high performance for the

combinations.